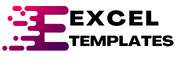

Streamline Your Manufacturing Process with Our Bill of Materials Excel Template

In the world of manufacturing, managing costs and ensuring efficient production is crucial to maintaining profitability and staying competitive in the market. One way to achieve this is by closely monitoring the Bill of Materials (BOM) for your products. To make this task easier and more organized, we’ve designed a versatile Bill of Materials template in Excel format, which will help you track the cost of product manufacturing effectively.

What is a Bill of Materials?

A Bill of Materials (BOM) is a comprehensive list of all the components, materials, and assemblies required to manufacture a product. It serves as a blueprint for production and provides a detailed breakdown of the costs involved in manufacturing each product. By using our Excel template, you can efficiently manage and monitor the cost of raw materials, labor, and other expenses associated with the production process.

Key Features of Our Bill of Materials Template

- Comprehensive Component Listing: The template enables you to list all the components, materials, and assemblies required for manufacturing your product. This ensures that you have a complete understanding of the resources needed and can effectively manage your inventory.

- Cost Breakdown: Our BOM template allows you to input the cost of each component, material, and assembly. This feature provides you with a detailed breakdown of the total cost of manufacturing your product, making it easier to monitor expenses and identify cost-saving opportunities.

- User-Friendly Interface: The Excel template is easy to use and customize to fit your specific needs. The intuitive design makes it simple for users of all skill levels to navigate and manage their BOM data effectively.

- Data Security: Since the template is stored on your computer or preferred storage device, you can ensure the security of your BOM data without relying on third-party software or online services.

Conclusion

Efficiently managing your Bill of Materials is essential for controlling production costs and maintaining profitability. By using our versatile Bill of Materials template, you can effectively monitor and manage the cost of product manufacturing. Download the template today and streamline your manufacturing process for better cost control and improved productivity.

Explore our other Bill of material templates: