Prepare Multi-Level Bill of Materials with Our Comprehensive Excel Template

In complex manufacturing processes, managing product costs and production efficiency becomes more challenging. A multi-level Bill of Materials (BOM) is a critical tool in addressing these complexities. In this blog post, we’ll discuss the concept of a multi-level BOM, its importance, and how our versatile Excel template can help you effectively manage and control your product costs.

What is a Multi-Level BOM?

A multi-level BOM is an advanced form of a Bill of Materials, which provides a hierarchical representation of all components, materials, and assemblies required to manufacture a product. It organizes the information in multiple levels, where each level represents a sub-assembly or a sub-component of the final product. This structure allows manufacturers to understand the relationships between various parts and assemblies more easily, making it especially useful for complex products with numerous components and sub-assemblies.

Industries and Scenarios Benefiting from Multi-Level BOM

- Automotive Industry: The automotive sector involves the production of highly complex products with thousands of components and sub-assemblies. A multi-level BOM is crucial for managing the production process, controlling costs, and ensuring quality standards are maintained.

- Aerospace and Defense: Aerospace and defense products, such as aircraft and satellites, have intricate designs and require precision engineering. A multi-level BOM helps manufacturers streamline production planning, manage inventory, and maintain stringent quality requirements.

- Electronics and High-Tech: Electronic devices and high-tech products, like smartphones and computers, consist of multiple layers of components and sub-assemblies. A multi-level BOM allows manufacturers to efficiently manage the procurement and assembly of these parts and accurately estimate the overall production cost.

- Medical Devices: The manufacturing of medical devices, such as diagnostic equipment and surgical instruments, involves a high level of complexity and strict quality standards. A multi-level BOM is essential for managing the production process, controlling costs, and ensuring compliance with regulatory requirements.

- Industrial Machinery and Equipment: Heavy machinery and equipment used in industries like construction, mining, and agriculture are composed of numerous components and sub-assemblies. A multi-level BOM helps manufacturers oversee the production process, manage inventory, and maintain quality standards.

- Consumer Products and Appliances: Consumer goods, such as appliances and furniture, often consist of multiple components and sub-assemblies. A multi-level BOM facilitates better production planning, inventory management, and cost control in these industries.

Importance of Multi-Level BOM

- Enhanced Production Planning: A multi-level BOM provides a granular view of the resources and sub-assemblies required at each stage of the manufacturing process. This detailed information enables better production planning, resource allocation, and inventory management.

- Streamlined Communication: By displaying the relationships between various components and sub-assemblies in a hierarchical structure, a multi-level BOM facilitates clear communication and collaboration among different departments, such as engineering, procurement, and manufacturing.

- Accurate Cost Estimation: A multi-level BOM allows for precise cost estimation at each level of the production process. This accuracy helps manufacturers identify cost-saving opportunities, set appropriate pricing, and develop accurate budgets.

- Improved Quality Control: With a comprehensive overview of all sub-assemblies and components, a multi-level BOM makes it easier to ensure that quality standards are met throughout the production process.

- Efficient Product Updates: The hierarchical structure of a multi-level BOM simplifies the management of product changes and updates, allowing manufacturers to respond quickly to market demands and evolving customer needs.

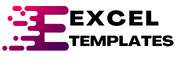

How Our Multi-Level BOM Template in Excel Format Can Help You

Our multi-level BOM Excel template is designed to help you efficiently manage and control your product costs in complex manufacturing processes. Here’s how our template can benefit you:

- Hierarchical Organization: The template’s structure allows you to input components, materials, and assemblies in a hierarchical manner, making it easy to visualize and understand the relationships between different elements of the product.

- Detailed Cost Breakdown: With our template, you can input the cost of each component, material, and assembly at every level of the BOM. This detailed breakdown enables you to closely monitor expenses and identify opportunities for cost savings.

- Customizable and Adaptable: The template is flexible and can be tailored to suit the unique requirements of your specific manufacturing process, ensuring that you have complete and accurate information on the resources required for your product.

- User-Friendly Interface: The Excel template is intuitively designed and easy to navigate, allowing users of all skill levels to manage their multi-level BOM data efficiently.

- Data Security: Since the template is stored on your computer or preferred storage device, you can ensure the security of your multi-level BOM data without relying on third-party software or online services.

Conclusion

A multi-level Bill of Materials is an essential tool for managing complex manufacturing processes, enabling better production planning, cost control, and quality assurance. By using our versatile multi-level BOM Excel template, you can effectively oversee and monitor the cost of product manufacturing at every stage. Download our template today and gain control over your product costs with a comprehensive and structured multi-level Bill of Materials.

Explore our other Bill of material templates: